Where is LV Made: Exploring the Origins of Louis Vuitton Bags

When it comes to luxury fashion, few brands are as iconic and internationally recognized as Louis Vuitton. With timeless designs and meticulous craftsmanship, the Louis Vuitton brand has become a symbol of sophistication and prestige, much like the name Coco Chanel in the fashion world. But have you ever wondered where these highly contested handbags truly originate? The origin of a Louis Vuitton bag lies in tradition, utmost attention to detail, and a history of artistry. This article will take you on an exquisite journey in search of the origins of Louis Vuitton bags, while also exploring the exhaustive production process and the absolute standards that the brand adheres to. Whether you consider yourself a fashion aficionado or someone with a casual interest in the story behind the famous monogram, this exploration will deepen your understanding of the craftsmanship and legacy of the established Louis Vuitton.

Introduction to Louis Vuitton's Brand Heritage

The Louis Vuitton name traces the brand history across the realm of luxury trunk making, which began in 1854 with a small workshop in Paris, France. The name was once strongly associated with the Damier pattern. Over the years, the company has become synonymous with craftsmanship, innovation, and timeless design. The monogram canvas, introduced by Georges Vuitton in 1896, has become an international symbol of the brand's outstanding quality and exclusivity. Shifting away from the modern and super-technological approach towards supreme handcrafted traditions, Louis Vuitton has set a new facet through its product innovations, art, and legacy of excellence.

Overview of Louis Vuitton's Legacy

The legacy of Louis Vuitton is built on the simultaneous interplay of masterful craftsmanship, skillful design, and an unwavering commitment to quality. Since its founding in 1854, the company has set standards within luxury fashion, offering products bearing the trademark monogram canvas alongside timeless leather products. A balanced mix of tradition and contemporaneity has fanned the flames of inspiration within Louis Vuitton for the luxury consumer, all the while upholding its symbolic status of elegance and exclusivity.

Significance of Louis Vuitton Bags in Fashion

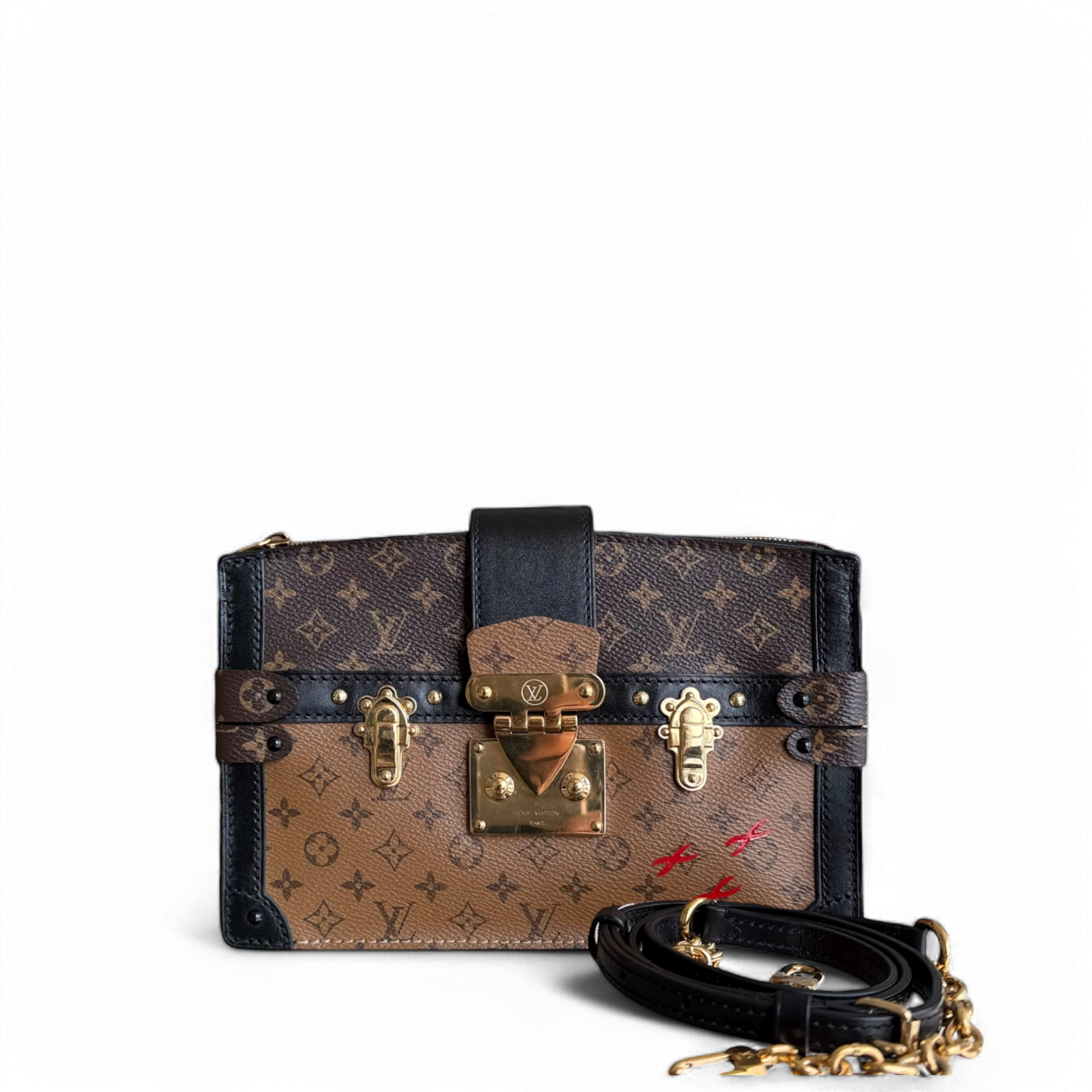

Louis Vuitton bags occupy a significant space in the fashion industry due to their excellent craftsmanship, timeless designs, and status as high-end symbols of luxury and exclusivity. Every bag is meticulously crafted with the finest materials, complementing the brand's commitment to innovation and quality. Their designs are iconic, such as the monogram canvas, which is readily recognized in the world of aesthetics and holds a high-priced reputation. Besides, many consider Louis Vuitton bags a worthy long-term investment, given their price appreciation over time, thanks to a nearly restricted supply and the ever-growing demand of collectors and fashion lovers worldwide.

Understanding the Global Appeal of LV

Louis Vuitton's worldwide appeal lies in the blend of timeless craftsmanship, exclusive designs, and a strong brand heritage. Committed to quality and continuous innovation, the brand ensures that all its products meet the highest standards, making them a coveted object among customers worldwide. The distributed strategy is complemented by targeted promotions of select collections, which contribute to its aura of exclusivity and thereby enhance its desirability. They also enter the scene in cultural polls, sometimes fraternizing with influential celebrities to rebrand this image as a mark of class and class distinction among makers.

Historical Production Locations

Early Manufacturing Practices in France

The history of craftsmanship at Louis Vuitton dates back to the establishment of the brand in 1854 in Paris, France. In their early years, the brand primarily produced sturdy and elegant trunks and luggage, making a lasting impression that would ultimately evolve into the iconic Great Louis Vuitton logo. At this time, artisanal methods governed all production lines, with each piece being crafted by hand —a skill that was part of a long line of artisanal traditions. These older workshops, based mostly in Asnières-sur-Seine, became centers of innovation that led to the development of products such as the flat-topped trunk, which was revolutionary for travel luggage, as it could be stacked.

By the late 19th century, French manufacturing units began to place greater emphasis on the use of high-grade materials, including superior leather, coated canvas, and sturdy hardware. The environment of good materials sanctified the well-being of the item. In other words, each product was designed with the idea that it should last forever and withstand various travel conditions. The Asnières workshop remains a testament to the brand's value consciousness today. It blends traditional methods with contemporary approaches to preserve the memory of its formation.

Expansion to Other Countries

Global expansion has been etched into history as a testament to strategic planning and adaptability in diverse markets. By the mid-century, the brand had expanded into key cities such as New York, Tokyo, and London, marking the beginning of its transformation into a global luxury symbol. Presently, Louis Vuitton is operational in over 50 countries, with more than 460 stores worldwide. This retention is supported by a concerted localization effort, whereby each store responds to the cultural and stylistic characteristics of the region in which it is embedded, all while retaining the brand's signature identity.

The Asia-Pacific region, particularly China, has long been one of Louis Vuitton's key markets due to the increasing demand for luxury goods among the middle- and upper-class segments. Furthermore, Middle Eastern countries, including the UAE and Saudi Arabia, have been pivotal to the brand's upliftment due to a clientele with higher disposable income and a preference for ostentatious designs. Furthermore, the digital transformation provided a significant boost to this brand's growth, as e-commerce channels became available across continents, thereby making the brand accessible in markets with limited physical presence.

By investing in innovation, maintaining consistency of quality, and conducting in-depth studies of global customer behavior, Louis Vuitton sustains its position in both developed and emerging markets. These factors continue to propel the brand's leadership in the international luxury goods market.

Impact of Historical Events on Production

Historical events with a significant impact on luxury goods production are evident, as seen in the case of Louis Vuitton. Similarly, during the Second World War, the restricted circumstances of global conflict heavily influenced the availability of raw materials and labor. The Louis Vuitton company managed to stay afloat during challenging periods by diversifying its product range, thereby demonstrating its resilience and ingenuity.

In the present times, events like COVID-19 have continued to transform production systems. Disruptions in supply chains, coupled with factory shutdowns in important production zones, necessitated consideration of alternative approaches to inventory management and production. Industry insiders have observed that luxury brands, such as Louis Vuitton, have harnessed the power of digital and automation technologies to minimize delays and ensure impeccable quality in their craftsmanship. Production strategy, besides, now has sustainability objectives as a critical consideration. The fact that these production considerations are increasingly consistent with environmentally friendly standards is not just a response to putative regulatory frameworks, but also, importantly, to consumer expectations, which themselves confirm a contemporary, reliable luxury brand.

Together, historical and modern developments underscore the interconnectedness between world events and our production landscape, thereby emphasizing adaptability and strategic foresight as vital in long-term success.

Current Manufacturing Sites

Made in France: The Heart of LV Production

France has long been at the heart of Louis Vuitton's manufacturing operations, representing all that this label stands for in terms of craftsmanship and heritage. The company operates several important workshops across this country, among them the historic workshop in Asnières-sur-Seine, dating to 1859, where many bespoke orders and limited-edition pieces are produced. It is the place where the world has come to recognize Louis Vuitton for quality and attention to detail, along with artisans who pass their knowledge down to new generations.

In the world of Louis Vuitton, Asnières is just one small spot on the map. The workshop expands its operations into other key areas of France, including Beaulieu-sur-Layon, Ducey, and Saint-Donat-sur-l'Herbasse. These facilities remain at the forefront of new production techniques, yet never lose sight of traditional craftsmanship. Each workshop is responsible for different lines of products, ranging from leather goods to trunks and other luxury accessories, to ensure a streamlined production flow and the utmost level of quality control.

Local manufacturing, with a particular focus on supporting French artisanal heritage, forms the backbone of the sustainability strategy. Using materials of European origin and concentrating production near its core end-market minimizes the logistical footprints and enforces good labor practices. Louis Vuitton was reported to have hired nearly 4,000 artisans in its French facilities, the largest number today, drawing attention to its investment in domestic talent and the preservation of luxury craftsmanship.

Made in the USA: A New Era for Louis Vuitton

The expansion of Louis Vuitton into the United States marks a critical milestone in its operational strategy to target a burgeoning market. The brand boasts several production facilities in the U.S., including its workshop in Alvarado, Texas, which debuted in 2019. This workshop enables Louis Vuitton to efficiently meet local demand while maintaining the highest level of craftsmanship. Employing several hundred artisans well-versed in leather craftsmanship, this workshop crafts and finishes some of the company's most iconic leather goods to the exacting specifications upheld by Louis Vuitton in every country involved in its supply chain.

Industrious and timely, the presence of domestic production facilities also cut down delivery times to American customers, thereby solving logistical issues with greater efficiency and sustainability. Additionally, this presents an opportunity for the brand to capitalize on the expansion of regional manufacturing traditions, embracing quintessential French luxury. This investment is thus a statement by the company regarding its objectives of proximity to markets and sustainable production, which aim to establish it as a global leader in luxury fashion.

Other Global Manufacturing Locations

The company operates manufacturing facilities at various strategic locations worldwide to fulfill production needs and meet regional market demands. These include workshops located in Italy, capable of producing fine leather goods; another set of workshops in Spain for making shoes; and finally, production sites in Switzerland for fine watchmaking. Every location gets chosen for its expertise in one craft, ensuring it maintains quality in all product categories.

Craftsmanship and Materials Used in Louis Vuitton Bags

The Art of Craftsmanship in LV Bags

Louis Vuitton bags are crafted with great pride by skilled artisans, who combine traditional methods with the latest innovations. Artisans undergo rigorous training for a period that can extend up to one year to learn the necessary skills to manufacture every product, hence guaranteeing the integrity of an LV product. The first step would be to cut materials, such as the Louis Vuitton signature Monogram Canvas and fine leathers, with precision tools to ensure exact dimensions.

Each bag is meticulously assembled by hand, with attention to detail that extends from logo placement to patterns that align seamlessly at every crease. For instance, the Monogram Canvas has been designed specifically to allow pattern alignment; this marketing speaks volumes to the level of precision associated with the brand. Stitching is an essential aspect of the construction process, where artisans use strong, wax-coated linen thread, with an average of over a thousand stitches per bag, thereby guaranteeing durability and a visually appealing appearance.

Louis Vuitton places high integration levels of quality assurance checks. Some tests for any bag include the tensile strength of the handle, as well as environmental tests simulating wear over time. These tests are another name for evaluating the material's resistance to conditions that may cause it to degrade over time. This ensures durability and timeless appeal, as the customer expects. Traditional manufacturing, with the infusion of advanced manufacturing techniques, equips LU with the opportunity to ensure that each bag really is one of the world's best.

Materials: Sourcing and Quality Standards

Louis Vuitton is committed to sourcing only the finest raw materials, with quality and sustainability considered on an equal footing. These primarily comprise premium leathers, ranging from cowhide to exotic skins, meticulously crafted by the best tanneries with decades of experience in their craft, ensuring the highest quality is achieved in LV merchandise. To maximize such treatment, utmost care is taken when subjecting them to rigorous procedures for waterproofing and UV resistance, while also retaining their natural texture and appearance.

In its material repertoire, Louis Vuitton utilizes a wide range of fine textiles, including coated canvas and jacquard fabrics, renowned for their exceptional durability and aesthetic beauty. For its hardware components, such as clasps and zippers, the brand uses metals like brass and Zamak, which are sustainably sourced and ensure longevity. These materials from Louis Vuitton consistently exceed industry standards in terms of tensile strength, abrasion resistance, and environmental sustainability.

Sourcing-wise, the brand places strong emphasis on sustainability. It tends to align with global environmental goals by using materials certified by independent organizations such as the Leather Working Group, which evaluates ecological compliance in tannery operations. Given such adherence to stringent sourcing and quality standards, every single product can qualify as a testament to the brand's uncompromised dedication to excellence.

Authenticity and the Importance of Craftsmanship

Craftsmanship plays an indispensable role in marketing a company's brand as genuine, as it embodies the conscientious quality, heritage, and skill that are extolled in each product. According to research, more than 70% of consumers equate quality craftsmanship with authenticity, which significantly influences their purchase decisions. Such high-quality products further sustain reputation, which, along with trust, has become attractive to customers in the balance of equal amounts of heritage and innovation. By employing the best modern technology and precision tools alongside traditional techniques, they make the product even tougher and more efficient, thereby fulfilling the expectations of today's customers. Staying true to craftsmanship will enable brands to honor their rich heritage and cater to the growing consumer demand for well-crafted, sustainable, and purposeful designs.

Sustainability Initiatives by Louis Vuitton

Commitment to Sustainable Practices

Louis Vuitton has a strong sustainability framework that helps minimize its environmental impact while ensuring that every product is meticulously crafted. The company's principles include circular creativity initiatives such as recycling, designing to last, and minimizing the waste generated during the production process. For example, the use of raw materials originating from sustainable sources has been significantly increased, particularly leather, which comes from Tanneries certified by the Leather Working Group that adhere to strict environmental standards.

Additionally, the company works to reduce its own environmental impact by utilizing renewable energy across its entire range of activities. More than 50% of Louis Vuitton's workshops and stores operate using renewable energy, and the brand has ambitious objectives to increase that percentage. In addition, the company invests in sustainable innovations, including the application of eco-design principles to its products and packaging-based solutions that utilize recycled and recyclable materials.

Louis Vuitton intends to participate in global initiatives, such as the Science-Based Targets initiative (SBTi), to ensure that its climate action plans are aligned with the limits on global warming as outlined in the Paris Agreement. By 2025, the Louis Vuitton brand has set a target to reduce greenhouse gas emissions by 55% from the 2019 baseline, proving once again to be a leader in sustainability. These efforts confirm Louis Vuitton's unwavering commitment to the principle that sustainability should inform every major business decision made by the company.

Environmental Impact of Manufacturing

The manufacturing processes in the fashion industry generate environmental problems, particularly in terms of resource consumption and waste production. Textile manufacturing-the manufacture of leather and synthetic materials commonly used in the production of luxury goods-requires enormous amounts of water, energy, and raw materials. It is estimated that one kilogram of leather requires approximately 17,000 liters of water throughout its entire life cycle. For this reason, hazardous chemicals used in tanning and dyeing can contaminate water and soil if not properly disposed of or treated.

The other environmental factor resulting from manufacturing is carbon emissions. Studies show that the fashion industry accounts for 10% of the world's greenhouse gas emissions each year, primarily due to carbon-intensive methods and a heavy dependence on fossil energy sources, prompting brands like LVMH to adopt sustainability initiatives. This then calls on companies to switch to cleaner energy sources and enhance energy efficiency in their production processes.

Continuing further, waste remains a significant environmental problem, with millions of tons of textile waste generated annually. Some inefficient practices in the industry, along with unused scraps, contribute to landfills becoming a further ecological burden. The brands embracing sustainable practices are addressing these issues by investing in circular manufacturing processes, technologies that promote the efficient use of resources, and responsible material sourcing, thereby reducing their environmental footprint.

Future Goals for Sustainability

Pursuing a sustainable future has put companies in front of one of the key innovative solutions to lessen their environmental impact. The other key targets are those that extend circular economy principles, which primarily aim to reduce waste by reengineering products for reuse, recycling, and extended life. Based on historical trends and the latest results, circular design has the capability, on its own, to reduce global emissions related to manufacturing by up to 45% by 2050.

Another key objective is to achieve a net-zero carbon commitment. Many companies now employ science-based targets to achieve net-zero status, with some even pledging to do so by 2030. Renewable energies are key to this, with global clean energy technology investments surpassing $1 trillion per year since 2022.

As developing forces emerge in the areas of material innovations, bio-based textiles, lab-grown alternatives, and biodegradable packaging are also mentioned. These attempts are aimed at replacing conventional, resource-intensive materials and reducing pollution. By incorporating these mechanisms into their business operations, companies can address sustainability targets while providing both economic and environmental benefits in the long term.

Frequently Asked Questions (FAQs)

Q: Where are Louis Vuitton products made?

A: Louis Vuitton products are primarily made in France, where the brand's workshops are located. The company cherishes craftsmanship and quality above all.

Q: Are Louis Vuitton handbags made in China?

A: Many of the great acts of luxury brands produce their goods in China, but in reality, genuine Louis Vuitton handbags are, for the most part, made in France, Italy, and Spain. Some small leather goods can be made elsewhere, including Italy and Spain; these particulars are denoted on the product tags.

Q: The history of Louis Vuitton manufacturing?

A: The brand was established in 1854, and Louis Vuitton started as a trunk maker in Paris. Throughout, it has evolved into a fine and reputable leather goods house, producing handbags and bags while maintaining a strong commitment to craftsmanship and quality.

Q: What kinds of Louis Vuitton bags are produced?

A: Louis Vuitton bags that include iconic styles such as the Speedy, Keepall, and some handbag designs. Each bag represents the history of the house and its commitment to luxury.

Q: How does Louis Vuitton maintain its craftsmanship?

A: Louis Vuitton ensures excellent craftsmanship by having skilled artisans work in their ateliers. It is demanded that each product is created with excellence in mind, using only the finest materials.

Q: Are Louis Vuitton bags made somewhere else apart from France?

A: Most of the Louis Vuitton handbags and bags are made in France; however, in some cases, it may be possible for some manufacturers to manufacture these bags in other countries, such as Italy and Spain, depending on the item.

Q: Can Louis Vuitton made-in-the-USA handbags be sold?

A: It is possible to sell Louis Vuitton bags made in the USA, but these bags must be genuine, given that Louis Vuitton does not chiefly carry out manufacturing within the United States; indeed, the basis of resale rests on authenticity.

Q: What detail should I know in case I want to see the manufacturing place of the Louis Vuitton product?

A: Louis Vuitton products are made in various places, mainly in France, Italy, and Spain. The country of manufacture is typically specified on the product tag, which is crucial for authenticating stones.

Q: What makes a Louis Vuitton handbag special?

A: Louis Vuitton handbags are special because of their timeless designs, materials, and the artistry that goes into making the products. Each item testifies to the stature and heritage of the brand.

Reference Sources

1. Harvard Business School: Louis Vuitton: Luxury handbags coming off an assembly line-Discusses the history and manufacturing processes of the company.

2. Penn State University: Louis Vuitton Moves into U.S. - Emma Betz-Considers the spread of Louis Vuitton into different countries, including the U.S.

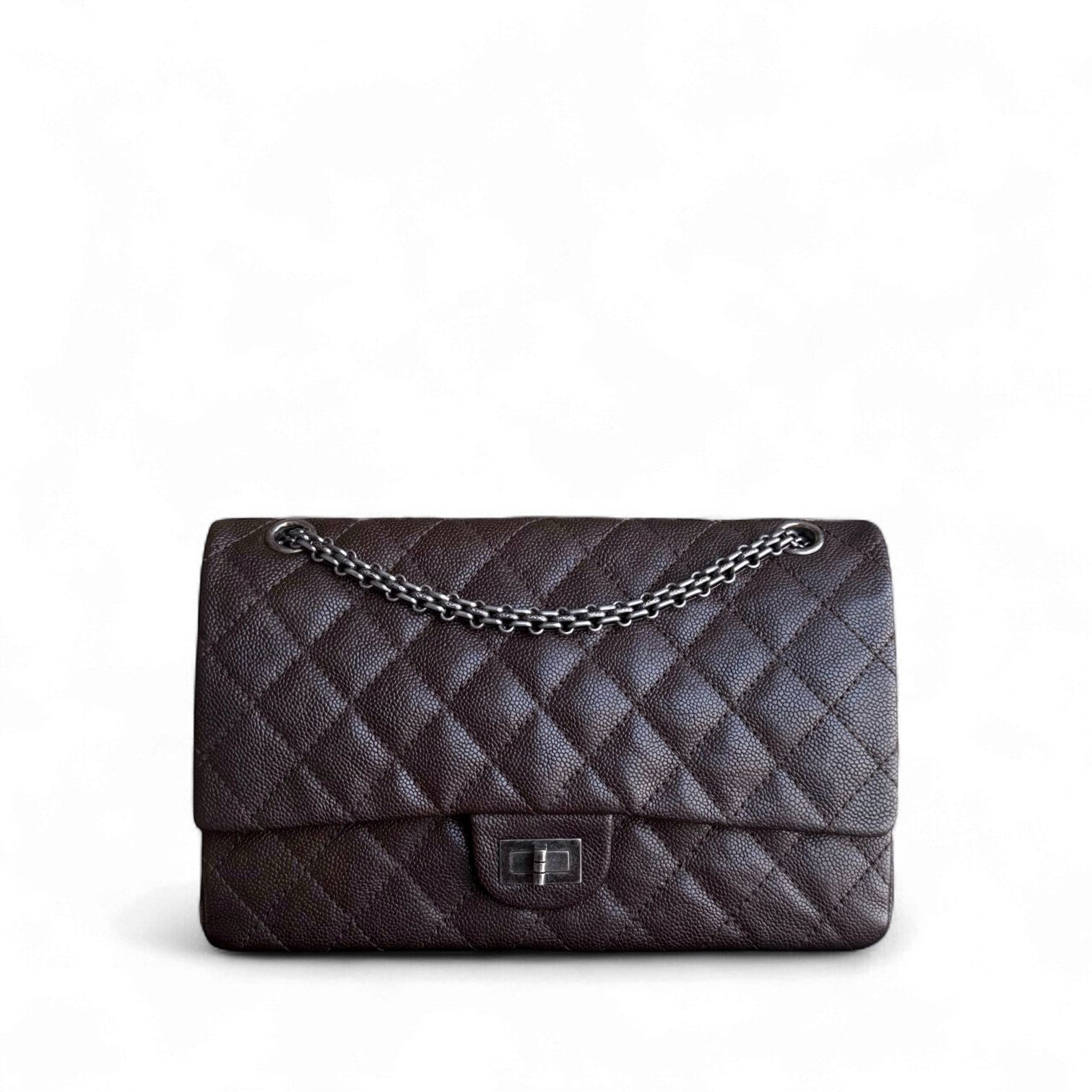

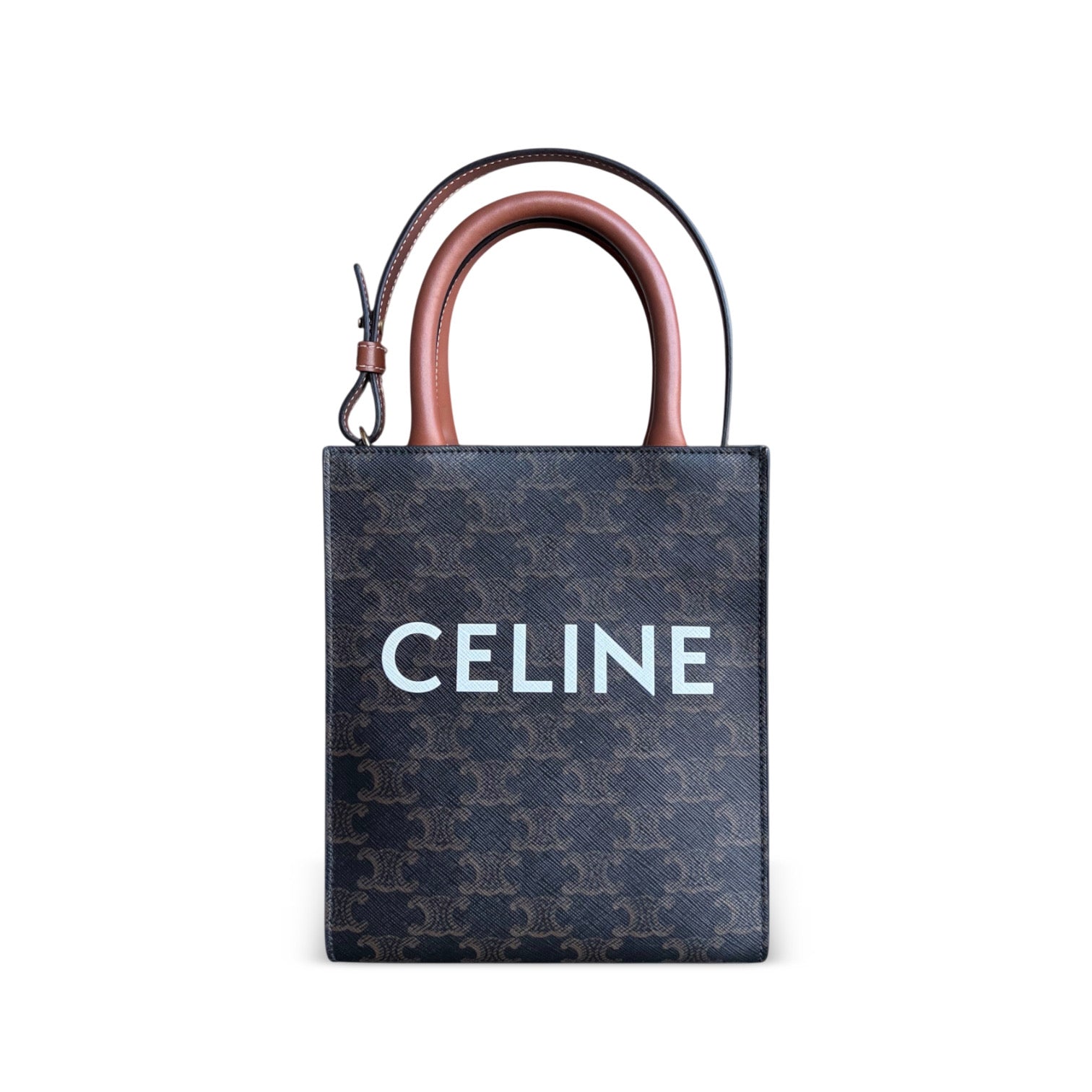

Contact Luxury Evermore should you need help with acquiring or building up your collection. There is a variety of brands with different styles, as well as sizes, and colors, for example, Hermes, Chanel, lv and Dior. If you are not lucky enough to find the bag you are looking for on our website then our concierge team will probably be able to order it for you. We provide 100% authenticity guarantee for all our bags, and any item sold on this site will be dispatched to you within one to two business days upon receipt of the payment.